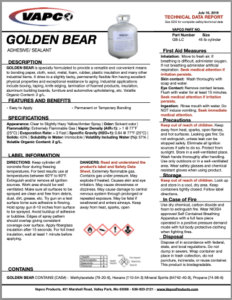

GOLDEN BEAR

GOLDEN BEAR is specifically formulated to provide a versatile and convenient means to bond paper, cloth, wood, metal, foam, rubber, plastic insulation, and many other industrial items. It dries tacky with a permanently flexible film, with resistance to aging. Industrial applications include things such as boxing, taping, knife edging, lamination of foamed products, insulation, aluminum building boards, furniture, and automotive upholstering, etc.

Note: Volatile Organic Content: 2 g/L.

Features and Benefits

- Easy to Apply

- Permanent or Temporary Bonding

Part Number; Size

- GB-LC 45 lb cylinder

Directions:

- Keep the cylinder off concrete floors during freezing temperatures. Use at temperatures between 60°F to 90°F.

- Extinguish and remove all ignition sources. Use in a well-ventilated area. Sprayed surfaces should be clean and free from debris, dust, dirt, grease, etc.

- Try gun on a test surface and then hold spray gun 8-10 inches from surface to be sprayed. Avoid the buildup of adhesive or bubbles. Edges of spray patterns should overlap.

- Apply fiberglass insulation after 15 seconds. For foil lined insulation, wait at least 1 minute before applying.

DANGERS & PRECAUTIONS

Read and understand the product’s label and Safety Data Sheet. Extremely flammable gas. It contains gas under pressure. May explode if heated. It causes skin and eye irritation. May cause drowsiness or dizziness. Damage to the central nervous system may happen through prolonged or repeated exposure. If the product is swallowed or enters airways it may be fatal. Keep away from heat sources such as sparks, open flames, and hot surfaces. Leaking gas fire: Do not extinguish, unless leak can be stopped safely. Eliminate all ignition sources if safe to do so. Protect from sunlight. Store in a well-ventilated place. Wash hands thoroughly after handling. Use only outdoors or in a well-ventilated area. Wear safety glasses and chemical resistant gloves when using the product.

Spray Tip Assembly Directions

When replacing your spray tip (or troubleshooting a leaking/clogged gun or one that will not stop spraying) … ensure that the spray tip is assembled in the order shown below.

Instructions:

- Place spray tip (No.3) into nut (No. 4). Ensure tip protrudes from nut.

- Place seat (No. 2) into nut (No. 4) with flat side facing (and sitting atop) spray tip.

- Screw assembled spray tip onto spray gun (No. 1).

- Tighten with wrench.

Important: Seat (No. 2) needs to be placed with flat side facing spray tip (protrusion facing spray gun). If the seat is positioned incorrectly, the spray gun may not work properly (leaking, clogging, constant spraying and other problems may arise).